Residence cooking —

Sam Zeloof’s creations current what’s attainable for minute-scale silicon tinkerers.

Tom Simonite, wired.com –

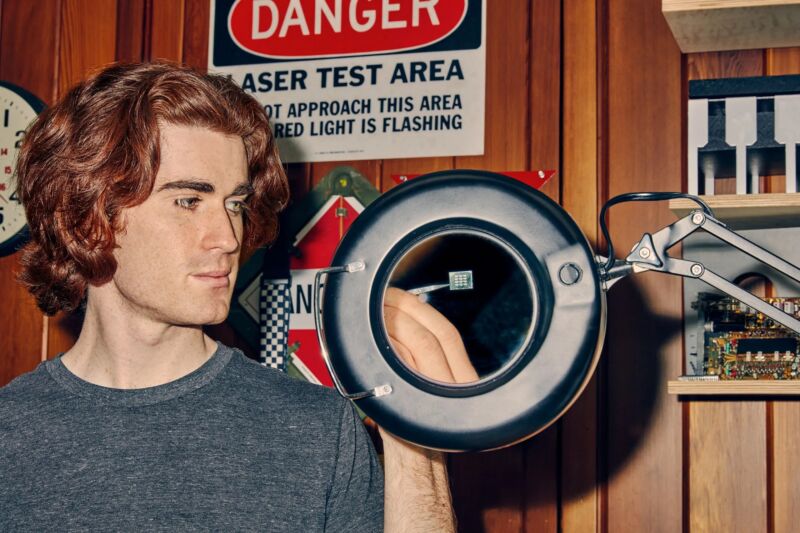

Develop / Sam Zeloof carried out this selfmade computer chip with 1,200 transistors, seen beneath a magnifying glass, in August 2021.

Sam Kang

In August, chipmaker Intel printed recent important factors about its concept to design a “mega-fab” on US soil, a $100 billion manufacturing facility the place 10,000 employees will make a model recent period of unparalleled processors studded with billions of transistors. The similar month, 22-One year-old Sam Zeloof introduced his have semiconductor milestone. It turned as quickly as executed by myself in his household’s New Jersey storage, about 30 miles from the place an important transistor turned as quickly as made at Bell Labs in 1947.

With a sequence of salvaged and selfmade devices, Zeloof produced a chip with 1,200 transistors. He had sliced up wafers of silicon, patterned them with shrimp designs the utilization of ultraviolet mild, and dunked them in acid by hand, documenting the course of on YouTube and his weblog. “Seemingly it’s overconfidence, however I indubitably safe a mentality that but some other human figured it out, so I’ll, too, regardless of the incontrovertible reality that perhaps it takes me longer,” he says.

Zeloof’s chip turned as quickly as his 2nd. He made an important, unparalleled smaller one as a extreme college senior in 2018; he began making particular person transistors a One yr sooner than that. His chips shuffle Intel’s by technological eons, however Zeloof argues handiest half of-jokingly that he’s making sooner development than the semiconductor trade did in its early days. His 2nd chip has 200 situations as many transistors as his first, a enhance price outpacing Moore’s laws, the rule of thumb coined by an Intel cofounder that claims the collection of transistors on a chip doubles roughly each two years.

Zeloof now hopes to match the size of Intel’s leap ahead 4004 chip from 1971, an important industrial microprocessor, which had 2,300 transistors and have become as quickly as veteran in calculators and different change machines. In December, he began work on an interim circuit design that might fabricate easy addition.

Develop / Zeloof says making it more easy to tinker with semiconductors would foster recent methods in tech.

Sam Kang

Exterior Zeloof’s storage, the pandemic has precipitated a world semiconductor scarcity, hobbling provides of merchandise from automobiles to sport consoles. That’s impressed recent passion from policymakers in rebuilding the US functionality to assemble its have computer chips, after a protracted time of offshoring.

Storage-constructed chips aren’t about to vitality your PlayStation, however Zeloof says his peculiar curiosity has blissful him that society would safe the benefit of chipmaking being extra accessible to inventors with out multimillion-buck budgets. “That indubitably extreme barrier to entry will make you huge danger-averse, and that’s unpleasant for innovation,” Zeloof says.

Zeloof began down the route to creating his have chips as a extreme college junior, in 2016. He turned as quickly as impressed by YouTube movies from inventor and entrepreneur Jeri Ellsworth through which she made her have, thumb-sized transistors, in a course of that included templates reduce from vinyl decals and a bottle of rust stain remover. Zeloof connect of dwelling out to repeat Ellsworth’s undertaking and take what to him regarded a logical subsequent step: going from lone transistors to constructed-in circuits, a soar that traditionally took a few decade. “He took it a quantum leap extra,” says Ellsworth, now CEO of an augmented-actuality startup often called Tilt 5. “There’s huge price in reminding the world that these industries that seem thus far out of attain began someplace extra modest, and likewise you might effectively presumably function that your self.”

Pc-chip fabrication is generally described as the world’s most refined and true manufacturing course of. When Zeloof began working a weblog about his targets for the undertaking, some trade consultants emailed to characterize him it turned as quickly as very now not going. “The motive within the relieve of doing it turned as quickly as in truth as a result of I believed it will presumably presumably effectively be amusing,” he says. “I needed to make an announcement that we should be extra cautious after we hear that one factor’s very now not going.”

Zeloof’s household turned as quickly as supportive however besides cautious. His father requested a semiconductor engineer he knew to offer some security suggestion. “My first response turned as quickly as that you just simply couldn’t function it. This can be a storage,” says Designate Rothman, who has spent 40 years in chip engineering and now works at a agency making expertise for OLED shows. Rothman’s preliminary response softened as he noticed Zeloof’s development. “He has completed points I might beneath no circumstances safe thought of us may function.”

Zeloof’s undertaking entails historical past besides to engineering. Neatly-liked chip fabrication takes narrate in providers and merchandise whose pricey HVAC programs take away each hint of mud that may additionally anguish their billions of greenbacks of equipment. Zeloof couldn’t match these programs, so he learn patents and textbooks from the Nineteen Sixties and ’70s, when engineers at pioneering corporations love Fairchild Semiconductor made chips at peculiar workbenches. “They document methods the utilization of X-Acto blades and tape and a few beakers, now not ‘We safe this $10 million machine the size of a room,’” Zeloof says.

Zeloof wanted to stock his lab with conventional devices, too. On eBay and different public sale web pages he discovered a prepared present of reduce price chip devices from the Seventies and ’80s that as quickly as belonged to since-shuttered Californian tech corporations. Nice of the devices required fixing, however previous machines are more easy to tinker with than authorized lab equipment. One among Zeloof’s handiest finds turned as quickly as a damaged electron microscope that price $250,000 within the early ’90s; he supplied it for $1,000 and repaired it. He makes use of it to leer his chips for flaws, besides to the nanostructures on butterfly wings.